S7 Tool Steel Hardness Before Heat Treat

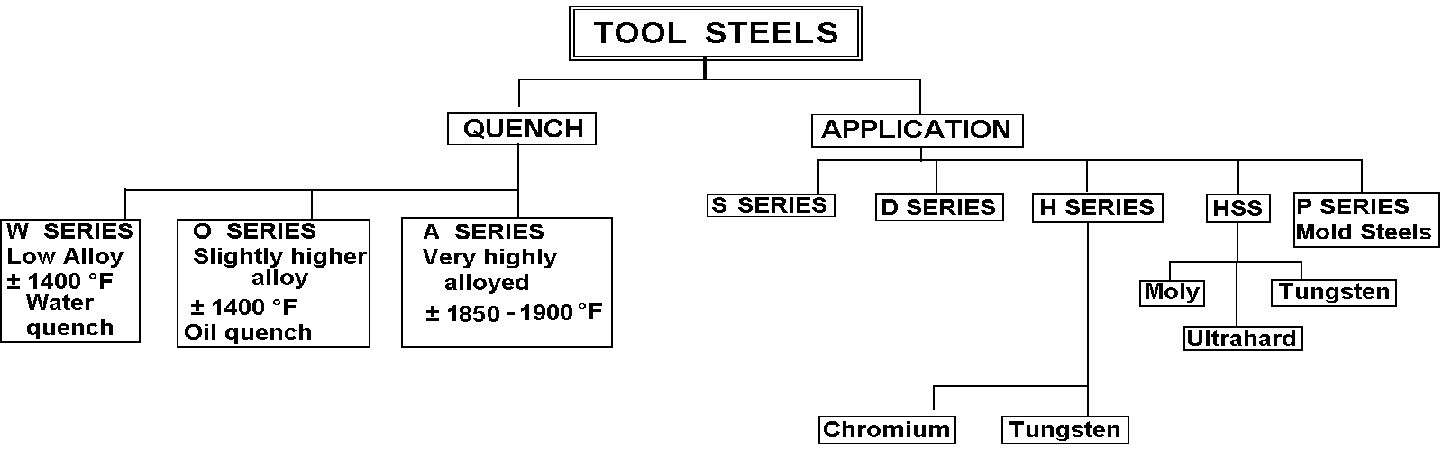

As a result dozens of tool steel types exist.

S7 tool steel hardness before heat treat. S7 also has medium hot work characteristics making it a versatile tool steel for both cold and warm shock applications as well as plastic molds that require high hardness. The combination of strength and high toughness makes it a candidate for a wide variety of tooling applications. Air hardening and versatile enough for use in both cold and hot work tooling make s7 suitable for a wide range of applications that require shock resistance size stability and. S7 shock resisting tool steel.

The specific properties of s7 d2 and a2 tool steels which are among the most popular in industrial and manufacturing applications today are discussed in further detail below. It can be quenched in air exhibiting minimal distortion on hardening. This process is commonly called interrupted oil quenching. However the aisi sae tool steel code categorizes tool steels based on basic application and material characteristics.

S7 is easy to machine in the annealed condition and can be readily heat treated. S7 an air hardening shock resisting tool steel is a classic example of a steel which will not develop full hardness in larger sections unless it is given an interrupted oil quench. S7 tool steel is produced and supplied to the machinist or tool maker in the annealed or soft condition. S7 tool steel is a shock resisting grade with superior impact properties combined with high toughness machinability and size stability during heat treating.